Granulated versus Ag Lime

The decision on which lime products to use, and its effectiveness, is often clouded in a little mystery. At Miriwinni Lime & Gypsum, we sometimes find that growers aren’t always aware of all the factors that need to be considered when comparing a granulated lime product with a powdered lime product.

There are many factors that need to be considered when spreading lime, with some of the main questions we regularly hear being;

- What is the quality of lime spread?

- Is there anything else added to the lime?

- What is the lime uptake rate of different sized particles – does size matter?

- How long does the lime last?

- How is the lime delivered and applied?

- What about the wind loses?

- Does the PH of soil have an impact on fertiliser uptake?

In the tables below we have attempted to answer these questions as simply and honestly as possible. It is often surprising to learn that there are some significant differences in the common applications of each product and the overall cost vs benefit of each.

Note: In comparing these products, we have used typical recommendations around application rates which are 300kg per acre for granulated lime and 1000kg per acre for powdered Ag-Lime.

Chemical Properties

Lime (or limestone) is Calcium Carbonate (CaCO3), and is the main product used for pH neutralising and calcium addition in soils. In most circumstances, the quality of lime used in granulated products is very similar to the lime used in our standard Ag-Lime products.

Granulated lime is generally made up of fine particles smaller than 75 micron which are held together using a binding solution. The binder varies from product to product and often constitutes around 5% of the total weight of the product meaning that only 95% of the granule is lime. In terms of manufacture, some products are made overseas and imported into Australia, while others are made in other states and transported to our region.

Our Ag-lime is 100% limestone which is sourced and mined in Far North Queensland. It is produced using milling and crushing processes at our mining locations in Mt Garnet and Chillagoe and distributed locally within the region. The production process of Ag-Lime uses no chemicals nor incorporates the addition of any additives.

Typical Granulated Lime

Pellet form (4 – 6mm)

95% Calcium Carbonate

5% Binder (to hold granule together)

98% CaCO3 @ 300kg / acre

98.60% Neutralising Value

Miriwinni Lime & Gypsum Ag – Lime

Powder form (0 – 0.800mm)

100% Calcium Carbonate

No binder

98% CaCO3 @ 1000kg / acre

98.71% Neutralising Value

Particle Sizing in Lime

As mentioned, the particle sizing of most lime granules is less than 75 microns, and to put this into perspective a human hair ranges from 40 – 120 microns in thickness. With sizing this small it is easy to see why, once the granule is broken down, these particles present a very large surface area, are easily absorbed into the soil, and start acting in a relatively quick way.

The common belief of Ag-Lime is that it’s much coarser than the lime used in the manufacture of granulated lime. In reality, this is both true and false. Ag-lime is a crushed and milled product, and in the process of crushing and milling, a large range of different size particles are produced. In our process, the maximum size of the particles in the product is controlled via screening to 0.8mm or 800 micron, while the smallest can often be down around 0.006mm or 6 micron.

The tables below provides a clear summary of the particle size distribution in both products. The laboratory testing shows there is in fact quite a large volume of Ag-Lime particles in the same 0 – 75-micron range as the granulated product.

The common belief of Ag-Lime is that it’s much coarser than the lime used in the manufacture of granulated lime. In reality, this is both true and false. Ag-lime is a crushed and milled product, and in the process of crushing and milling, a large range of different size particles are produced.

Typical Granulated Lime

(less unknown binder @ 5% typical weight)

0.000 – 0.075mm = 100% = > 285kg

0.075 – 0.300mm = 0% = no lime

0.300 – 0.850mm = 0% = no lime

0.850 – 1.000mm = 0% = no lime

Total lime purchased = 285kg

Binder Corrected NV = 93.67%

Miriwinni Lime & Gypsum Ag – Lime

(From independent laboratory sizing analysis)

0.000 – 0.075mm = 32% = 316kg

0.075 – 0.300mm = 31% = 312kg

0.300 – 0.850mm = 37% = 365kg

0.850 – 1.000mm = 1% = 7kg

Total lime purchased = 1000kg

Binder Corrected NV = 98.71%

Wind LossesWind is known to be a hinderance to the powdered lime application process and is often cited as one reason that growers consider a granulated product, and in this they would be correct. There are effectively no wind losses when applying a granulated lime product due to its size and weight.

The finer components of Ag-Lime are sometimes seen floating in the wind and while this can appear quite significant, it is only a very small fraction of the total lime that lands on the ground.

For comparison’s sake, let us assume that up to 5% of the smallest particles disappear in the wind as well as 5% of the next size fraction do the same, while above the 0.3mm size range it is safe to assume that all this product makes it to the soil. With these numbers in mind, the tables below give a comparison of how much of each size fraction gets to the soil in windy conditions.

|

Typical Granulated Lime

0.000 – 0.075mm = 0% loss = 285kg

0.075 – 0.300mm = N/A

0.300 – 0.850mm = N/A

0.850 – 1.000mm = N/A

Total lime on ground = 285kg

Miriwinni Lime & Gypsum Ag Lime

0.000 – 0.075mm = 5% loss = 300kg

0.075 – 0.300mm = 5% loss = 296kg

0.300 – 0.850mm = 0% loss = 365kg

0.850 – 1.000mm = 0% loss = 7kg

Total lime on ground = 968kg

Particle Size Efficiency – 1 Year

We all hear that the smaller sized particles in granulated lime act faster and are typically absorbed within 1 year, and this is correct. Test data shows that lime particles less than 300-micron (0.3mm) are 100% taken up into the soil in the first year, the key thing to understand here is that this happens automatically whether the particles are as part of a granule or not.

The interesting thing to consider is how much lime is taken up under each of the application scenarios we are considering in the first year, as both applications have a large percentage of product under this 300-micron level. In addition to this, there is still some uptake of lime from the larger particle size range as well and this can range between 10 to 50% depending on the particle size.

Therefore, the key consideration when comparing applications, is what is the total grading of all the particles in the mix? Not just one size fraction or the smallest fraction. The tables below provide some guidance as to how this take-up works.

Typical Granulated Lime

0.000 – 0.075mm = 100% = 285kg

0.075 – 0.300mm = N/A

0.300 – 0.850mm = N/A

0.850 – 1.000mm = N/A

Total soil uptake in 1 year = 285kg

Miriwinni Lime & Gypsum Ag Lime

0.000 – 0.075mm = 100% = 300kg

0.075 – 0.300mm = 100% = 296kg

0.300 – 0.850mm = 50% = 182.5kg

0.850 – 1.000mm = 10% = 0.7kg

Total soil uptake in 1 year = 685.2kg

Particle Size Efficiency – 3 Years (1 application)

The application of lime is sometimes applied in cycles longer than 1 year and in this section, we will consider a 3-year cycle. The first thing to understand, is that both applications use the same lime with the same chemical properties. One is not more potent that the other, and in a weight for weight comparison you get the same amount of lime and calcium no matter whether it is 100kg of granulated product or 100kg of powdered Ag-Lime.

The next question to consider, is how much is needed to maintain calcium levels and keep soil pH at a desired level. Is the 285kg supplied by the granulated choice enough for a 3-year period or is more required? Is the 1000kg from the Ag-Lime application too much? In all cases, it varies from paddock to paddock, and the answer is never clear.

The one thing we do know is that all the 285kg of granulated lime is taken up into the soil in the first year while around 685kg of the powdered Ag-Lime is also absorbed in this time.

What is most important to understand, is that the larger particle sizes in the Ag-Lime product continue to breakdown and are absorbed in years 2 and 3 of this cycle as well, and the representation of total uptake of both products over 3 years is shown below.

Typical Granulated Lime

0.000 – 0.075mm = 100% = 285kg

0.075 – 0.300mm = N/A

0.300 – 0.850mm = N/A

0.850 – 1.000mm = N/A

Total soil uptake in 3 years = 285kg

Miriwinni Lime & Gypsum Ag Lime

0.000 – 0.075mm = 100% = 300kg

0.075 – 0.300mm = 100% = 296kg

0.300 – 0.850mm = 100% = 365kg

0.850 – 1.000mm = 75% = 5.25kg

Total soil uptake in 3 years = 966kg

Application Process

The on-paddock application of these products is one of the key differences between both options. As we know, a granulated product can be incorporated into other spreading activities and result in no additional application cost or effort after the product has been delivered or collected from the supplier. Or, in some circumstances depending on timing and rotation, it may need to be applied on its own. This results in additional time and costs for its application.

Ag-Lime from Miriwinni Lime & Gypsum has several options. It can be purchased in bulk and applied with the same consideration for application costs as a granulated product, or it can be purchased, delivered, and spread without the need for any additional cost or time considerations. This presents a significant opportunity to maximise your time, save fuel and complete other activities.

Overall, the application value proposition is one which the individual operator must weigh up and factor into the overall application cost and decide which method suits them best.

Typical Granulated Lime

Transport to farm by grower

Spread by the grower

Using on farm equipment & fuel

Your time & cost….

Miriwinni Lime & Gypsum Ag Lime

Transported to farm by us

Spread by us

No additional cost….

Fertiliser & Nutrient Uptake

Irrespective of the lime option selected, lime as calcium carbonate is a critical soil ingredient that assists in maximising plant growth through the control of pH levels and nutrient uptake.

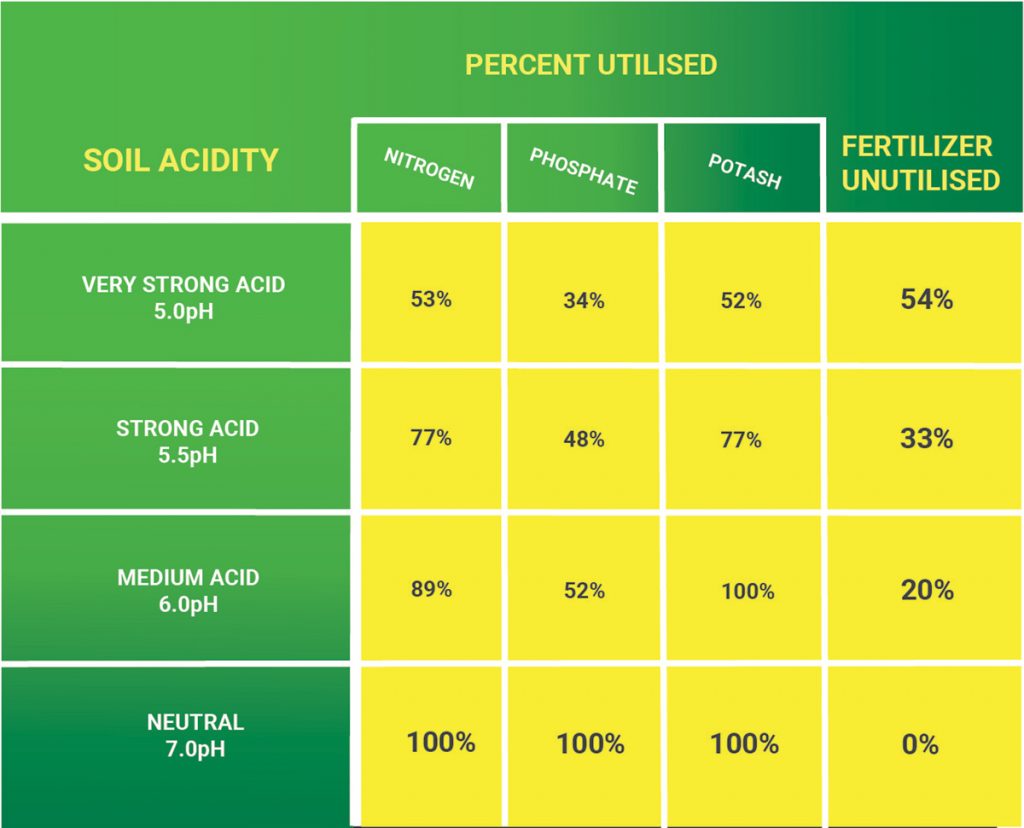

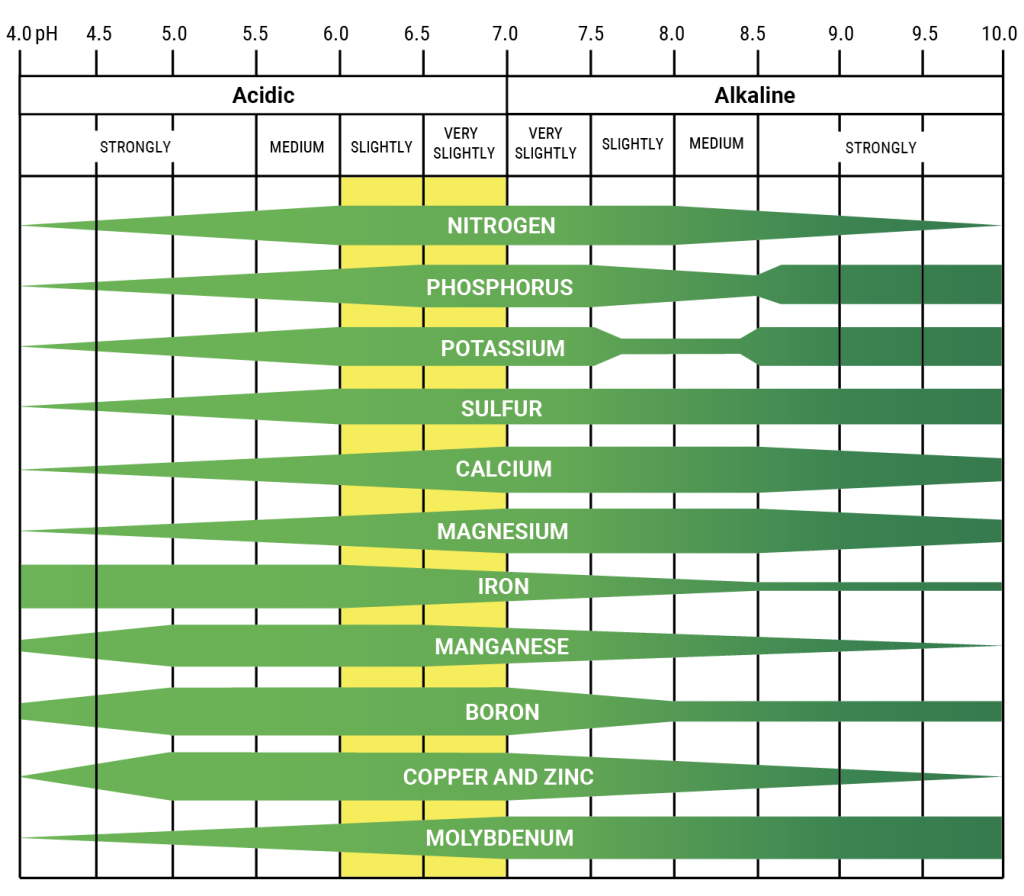

In soil with low pH levels the uptake of fertilisers can be reduced. If a soil has a pH at 5.0 or below (very acidic) this can have a significant impact on fertiliser efficiency and reduce their effectiveness by up to 50% depending on the type of fertiliser and soil properties.

The tables below provide some guidance on the relationship between optimal pH, fertiliser efficiency and nutrient availability.

The Final Word

From this comparison it is safe to say that the decision on a granulated product or a powdered product is ultimately the grower’s decision, however, a few key points have hopefully been clarified in this comparison and conclude that;

- The quality of lime used in both products is effectively the same

- Granulated lime contains an added binder

- Smaller particles have a faster uptake

- Larger lime particles continue to add benefit beyond the 1-year mark

- Powdered Ag-Lime contains a large portion of sub-0.3mm particles

- Powdered Ag-Lime experiences some losses in strong winds

- The cost of transport and application can be a driver in the total applied cost

For further information on our products please contact the team at Miriwinni Lime & Gypsum via [email protected] or call us direct on 07 4043 2200 and we can help you with your lime and soil conditioning options.